A non-hydrodewaxing catalyst was prepared by hydrothermal method using ZSM-5 as the main component doped with self-synthesized BCM zeolite. Catalytic behaviors of the catalyst was tested using FCC diesel oil and VGO as the feed.

The results showed that the catalyst had remarkable dewaxing effects, with freezing point reduction by 45 ℃ and high liquid yield under reaction temperature of 340 ℃ and LHSV 1 h-1. Diesel oil produced over the catalyst had higher octane number, low sulfur and nitrogen, and low freezing point, which meet the quality requirements of oil reformulation.

It is suitable for refining diesel from waste engine oil and refining gasoline and diesel from plastic oil. It can effectively remove the odor in the oil, reduce the wax content in the diesel, and improve the oxidation stability of the diesel.

Performance introduction Under non-hydrogen conditions, the use of high-silica molecular sieve catalysts with a certain pore structure can selectively crack long-chain n-alkanes and single-branched alkanes, while retaining cycloalkanes, multi-branched alkanes and aromatic hydrocarbons. Change, thereby reducing the pouring point of the distillate oil and converting heavy waxy diesel with high pouring point into light diesel with low pouring point. The catalyst is used in a non-hydrogen environment and limits the deposition of coke precursors in the molecular sieve channels, thus prolonging the reaction cycle and can be used in small and medium-sized refineries without hydrogen sources.

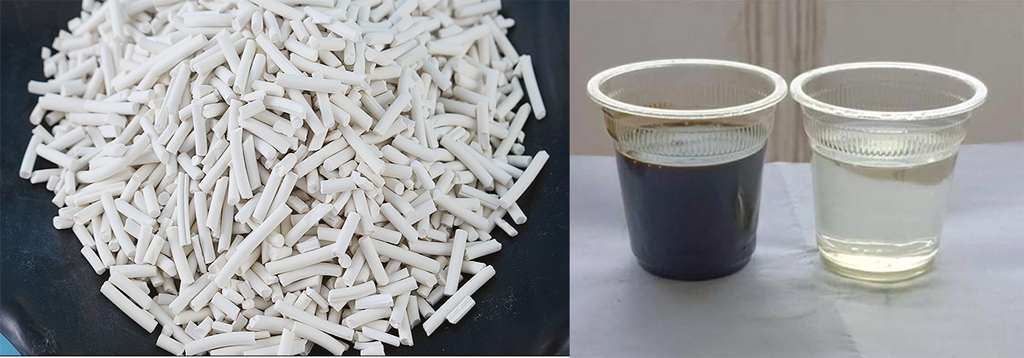

Product Specification

Shape | Cylinder | |

Diameter | mm | 2.7-3.3 |

Length | Mm | 20-50 |

Pore volume | ml/g | ≥0.50 |

Specific surface area | ㎡/g | ≥280 |

Crushing strength | N/cm | ≥120 |

Bulk density | kg/l | 0.5-0.60 |

Wearing loss | wt% | ≤1 |